The internet of things refers to using data instantaneously, from anywhere and globally; connected through the Internet, for the benefit of production.

Learn MoreRFID and Barcode Tracking Solutions

Intekel Automatización offers integral solutions with RFID (Radio Frequency) and / or Barcode technology for the requirements of traceability of assets, machines and tools, personnel control, factory automation, storage systems, logistics and distribution tracking. We combine such tracking technology with hardware, processing software and value-added services to offer you a complete custom solution.

The RFID and / or Barcode solution can allow your company to improve quality in the control of its operations, From the reception of materials, the in store selection, to the final delivery with the client with real-time information. Some of the quiality indicators that the implementation of a traceability solution complies with in its operations are the following:

- Manage inputs and outputs of products, tools and machinery in real time

- Improve customer safety, customer satisfaction and profit margin

- Ensure the quality of the products and compliance with regulations by monitoring the conditions of the merchandise while it is stored or during its transportation

Features

- Real-time integration with ERPs such as SAP, Oracle, SQL, etc.

- Hardware support for devices such as RFID readers, Barcodes, Tags, PLCs, Label printers, Smartphones and Hand Held devices

- Great diversity of tags for any application

¿What is RFID?

Radio Frequency IDentification, is a wireless and remote identification technology in which a reader device linked to computer equipment communicates through an antenna with a transponder (also known as a tag) by means of radio waves. The tags have the capacity to store data and transmit them wirelessly, through an integrated antenna, to a receiver that can be found between zero centimeters and several meters depending on the type of the tag.

The advantages of using this technology are as follows:

- Time reduction in the registration of inputs and outputs of physical inventories

- Improve business processes, responsiveness and performance

- Elimination of errors caused by the input of erroneous codes

- Reducir la pérdida de inventario, controlar los costos, administrar el inventario y prever las necesidades

- Improve productivity and supply chain efficiency

- Reduce inventory work and pinpoint bottlenecks

¿What is a Barcode?

The barcode is represented by bars and spaces representing small strings of characters. The barcode allows you to quickly recognize an item in a unique, global and unambiguous way at a point in the logistics chain and thus be able to perform inventory or check its associated characteristics.

The advantages of the application of this technology are the following:

- Quick control of the merchandise stock

- Fast data capture

- Barcode reading and printing equipment is flexible, inexpensive and easy to connect and install

- It has very low error percentages

- It allows to automate the registration and monitoring of the products.

Applications

Logistics:

Information regarding the location, status and condition of assets (containers, shelves, forklifts, vehicles, products, etc.) can increase operational efficiency within logistics environments. RFID and / or Barcode technology can be placed at the product, box, pallet or container level, ensuring traceability along the supply chain. The use of this technology is optimal to overcome the problems of distribution and production stocks control, allows to obtain total control of the inflows and outflows of merchandise that go to the warehouse.

Asset Control:

Identify and mantain an efficient control of tools, machinery and equipment inventories. Through the placement of RFID tags or Bar Code labels you will have an accurate record of the delivery and reception of fixed assets, pending assets of return, those equipments or machinery under repair, as well as an accurate inventory of your stocks.

Access Control to Distribution Center:

The entrance of vehicles and heavy trucks into a CEDIs can be automated through RFID technology. Each truck has an RFID tag that identifies it and communicates with an operating software, which controls the entry, weighing, loading and unloading of trucks.

Access Control:

With the use of RFID and / or Barcode technology placed in credentials, the system can identify in real time all the people that enter or leave your organization.

Manufacturing:

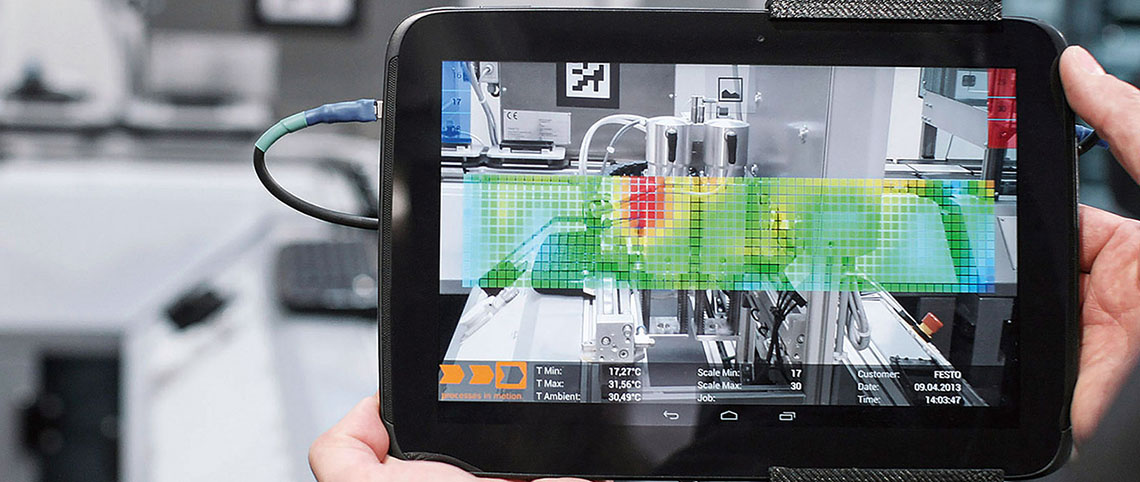

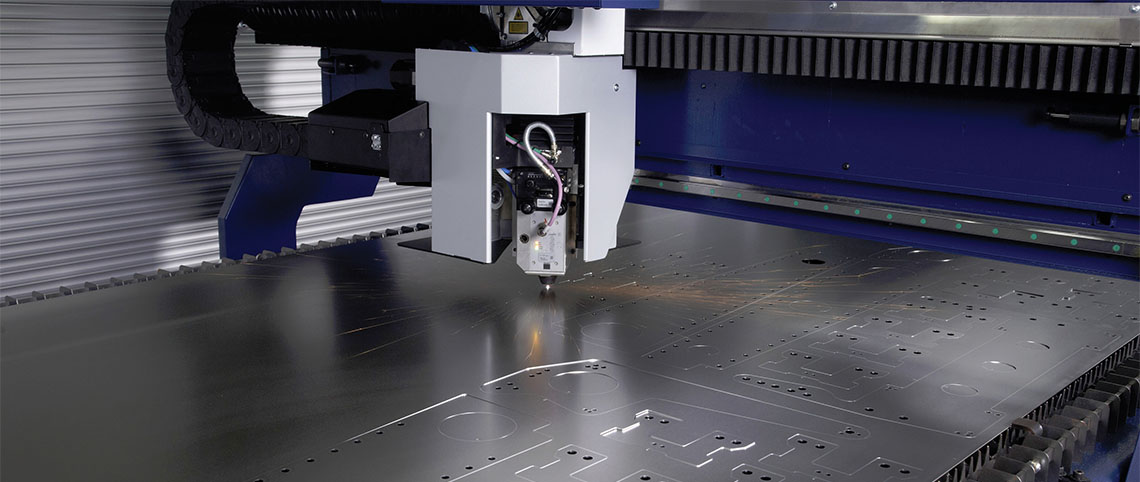

The use of these technologies applied to manufacturing processes, allows to obtain traceability and production control in different types of industries.

Tire Control:

With RFID technology you can have control over the tires that are used in a company's fleet of trucks. A vulcanized RFID tag is attached to each tire and assigned to a transport unit indicating the position in which it is located, and a history of the movements of said tire can be carried through a mobile application. The RFID tag can record information by tire; Mileage, tire wear, size, series, brand and model (both the tire and the unit), as well as pressure. For the reading of the tags on the tires, fixed antennas and / or mobile RFID terminals are used.

Medicaments Control

With RFID and / or Bar Code technology you can manage inventory expiration dates in real time and gain efficiency by improving product delivery. The identification of medicaments in manufacture and its subsequent follow-up in all stages of the distribution process towards wholesalers and stores allows to verify that the products are original and to reduce counterfeiting.