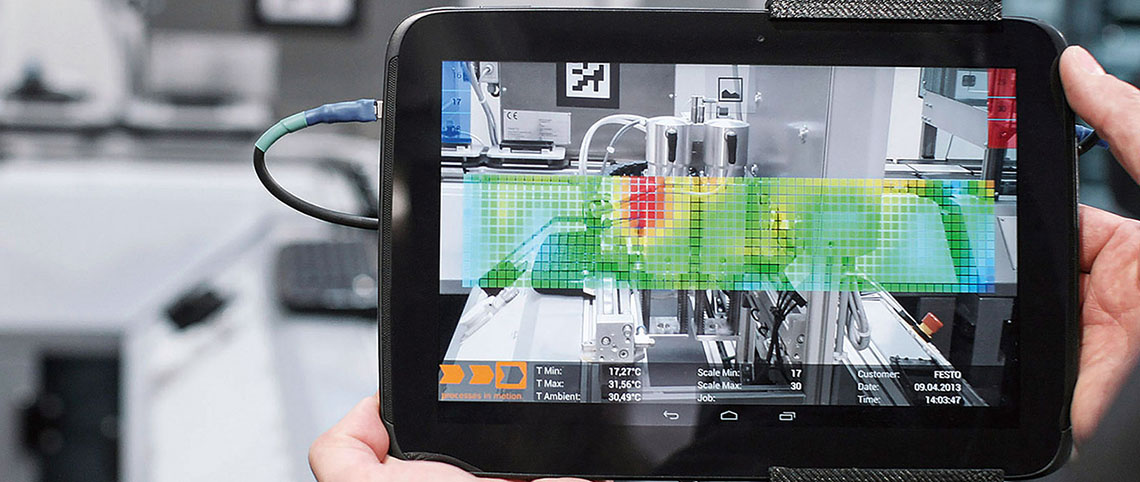

The internet of things refers to using data instantaneously, from anywhere and globally; connected through the Internet, for the benefit of production.

Learn MoreManufacture of CNC Machines

Router CNC

Cutting or engraving machine that works with a milling or drill tool to precisely and accurately carve the materials on three or more axes.

The CNC router works with a milling machine equipped with motors in each of its axes that are controlled by a computer using CNC (Computer Numerical Control).

CAD / CAM systems are used to generate the automatic machining program. The piece to be machined is designed on the computer in the CAD system (computer-aided design), then the CAM system (computer-aided manufacturing) takes all the design information and generates the cutting path that the tool has to follow to make the desired piece.

Features

- Accuracy, quality and speed: It can make movements that are not achieved manually

- Ability to realize diagonal lines, complex three-dimensional figures, execution of three-dimensional trajectories in the X, Y and Z axes

- Time optimization (reduction of time for cutting or engraving)

- Displacement System by linear bearings

- Control software for CNC machined

Applications

- Machining of solid surfaces

- Metalworking

- 2D and 3D Engravings

- Machining in 2 and 3 dimensions

- Machining of fiberglass materials

- Graphics and signage

- Machining and engraving in plastic

Cutting Types for CNC Machines

Waterjet cutting:

It makes cuts of a great quantity of materials including those that can not be subject to temperature variations. Waterjet cutting can be applied to metal, stone, marble, armored glass, ceramic, plastic, foam, wood, etc.

Router:

Can cut and engrave materials such as leathers, fabrics, foam, wood, aluminum, circuit boards, fiberglass and much more.

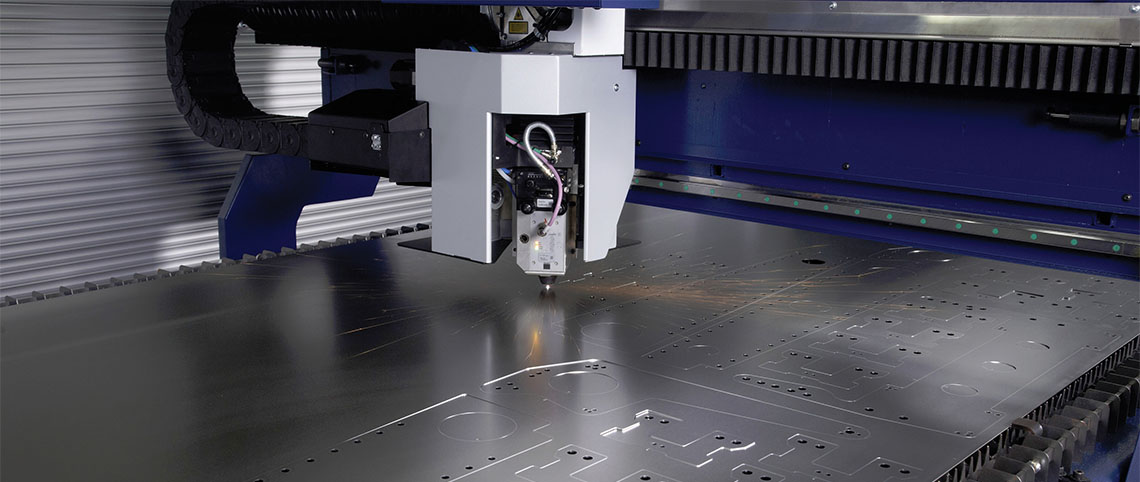

Laser:

Laser cutting machines produce a perfect cut and always provide crisp, clean cuts that do not fray. They offer greater accuracy and cutting speed, can cut or engrave materials such as glass, brass metal, wood, vinyl, rubber, paper, aluminum, leather, foamy, fabric, acrylic, etc.

Plasma:

Esta tecnología es útil para cortar y grabar cualquier material metálico conductor, especialmente acero estructural, acero inoxidable y metales no férricos que el oxicorte no puede trabajar. Puede cortar aluminio, acero inoxidable, cobre, láton y cualquier metal conductor.

Benefits

- Reducción de horas hombre para el proceso de fabricación

- Aumentar calidad del producto

- Mayor rentabilidad del producto

- Mayor precisión y calidad en la fabricación de piezas y materiales

- Corte en gran variedad de materiales

- Fácil procesamiento de productos de apariencia complicada

- Flexibilidad para el cambio en el diseño y en modelos en tiempo corto

- No se requieren operadores con experiencia

- Mayor seguridad en las labores industriales

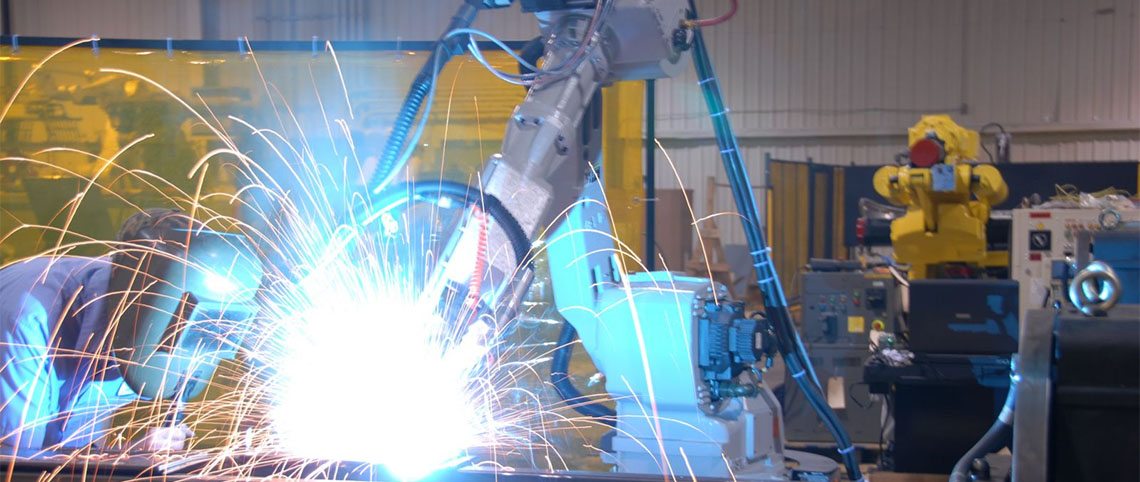

Robotic arms are used on a daily basis to increase productivity, safety and add value in countless industries.

Learn MoreEnergy is a determining factor for the growth, development, costs and competitiveness of companies.

Learn More