The development of customized software is the solution for when it is not possible to have a standard application that helps systematize the company's operational process, through the processing of information.

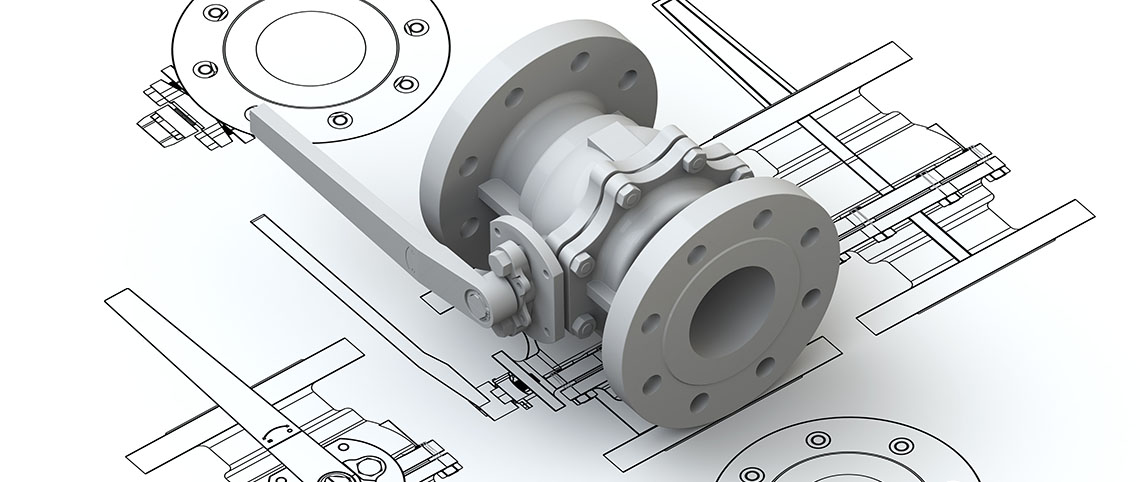

Learn MoreCAD/CAM Design

CAD (Computer Aided Design). It is the technology involved in the use of computers to perform tasks of creation, modification, analysis and optimization of a design.

CAM (Computer Aided Manufacturing). It refers to the use of computer numerical control (CNC) software applications to create detailed instructions (G-code), which govern numerically controlled (CNC) machine parts and manufacturing tools.

CAD/CAM integrates the design and manufacturing function, translating the final design specifications into detailed instructions for a machine.

CAD/CAM Systems

- Systems that facilitate the coding of instructions

- An easy-to-use interface is used

- The user graphically indicates the paths he wants on a CAD model

- The code is generated automatically

- They allow to simulate the result of a machining process

- Trajectiories can be generated manually or automatically

- Systems that allow collision detection

Benefits of CAD/CAM systems

By using CAD/CAM techniques you get factors that are vital for today's industry:

- Faster production cycles and higher quality processed products

- Engineering Analysis: It allows to determine how the design will behave and eliminate errors without the need to spend time and money constructing and evaluating real prototypes

- It means a great saving of time and a considerable reduction of costs

- Computer animation and process control

- Quality control and product reliability

- More efficient use of machinery

- Simultaneous machining

- Surface Machining

Solutions

CAD begins as a computerized technological engineering, while the CAM as a semiautomatic technology for the control of machines in numerical form in which you can make developments such as:

- 3D Design

- Production of drawings and document design

- Analysis of moving objects

- Basic geometric design

- Structural design

- Electronic design

- Hydraulic and pneumatic design

- Mechanical design

- Modeling and simulation of molds

- Finite Element Analysis

- Manufacture of prototypes

- Generation and simulation of numerical control programs

- Integrated circuit design

- Printed Circuit Board Design

- Design of electrical installations

- Analysis, verification and simulation of designs