The development of customized software is the solution for when it is not possible to have a standard application that helps systematize the company's operational process, through the processing of information.

Learn MoreAutomation Service

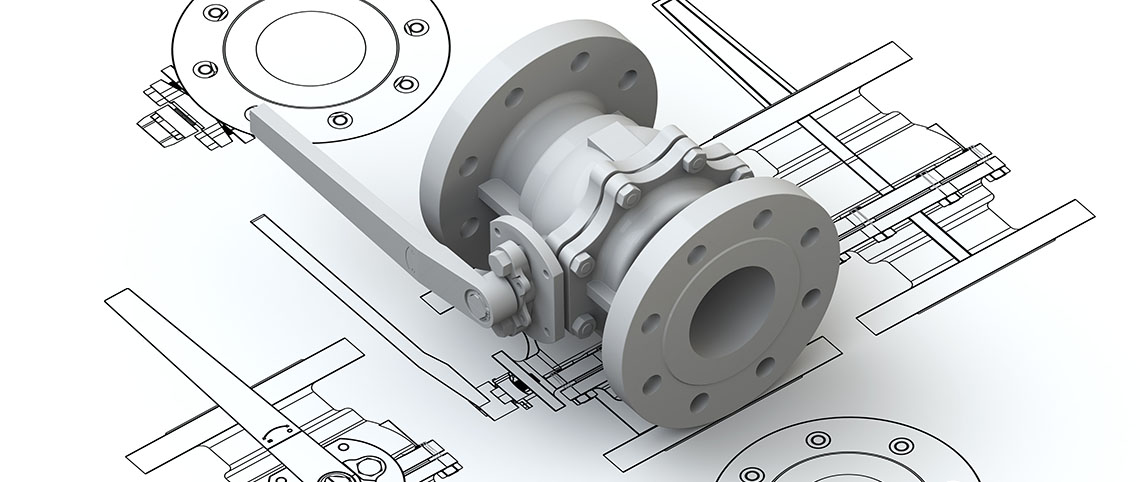

Intekel Automatización designs electronic, measurement and communication devices to efficiently and automate stages of industrial production for the areas of manufacturing, warehousing, labeling, packaging, supplies and shipping. The solutions developed by Intekel integrate proprietary technology as well as third-party technology, the company can manufacture from electronic cards, sensors and communication devices to control software or software for the monitoring of critical variables of a system.

Among the range of services offered by the company you can find: the automation and control of industrial processes, the design of HMI systems, the programming of PLCs from various manufacturers, the development of energy efficiency systems y the monitoring of critical variables involved in production processes such as temperature, relative humidity, pressure, pH, volume and weight, among other applications for the management of efficiency and yield of the production.

Benefits

We offer solutions for different sectors in everything related to automation, control and parts manufacturing.

- Cost Reduction: Process automation allows you to reduce errors, making them increasingly simple and economical

- Value Information: By performing an analysis of the times, performance and behavior of the processes, information is obtained that facilitates decision making for the continuous improvement of the processes

- Operational Efficiency Indicators Monitoring: Through monitoring software for critical variables at different stages of production, you can have real-time data on the number of packaged products, weighing systems, number of packages or sacks manufactured, failures in the manufacture of products, to mention a few key examples

Our Solutions

- Manufacture of Computer Numerical Control (CNC) machines and robotic arms to automate production phases

- Monitoring and control of devices that record temperature, humidity, pressure, pH, power consumption, etc., accessible through the Internet and in real time

- Control and Monitoring of Storage Systems: Silos, Tanks, Hoppers and Containers

- Production Labeling and Monitoring Systems

- Automation and process control

- HMI Systems (Scada, LabView, Autocad, etc.)

- Programming of PLCs from various manufacturers such as Siemens, RTP and ABB

- Energy Efficiency Systems

- Applications for efficiency management and production yield

- Machinery Statistics System to obtain data in order to efficiently predictive maintenance plan

- Design of CAD / CAM solutions for the manufacture of parts